Compiled for the EMM Lab by W. Kees Schuller. With thanks to Swati Mehta for web support, and Dwayne Collins for 3d file support

Original Design: https://www.instructables.com/4xiDraw/

Additional resources used: https://www.youtube.com/watch?v=GthY-ipk7Ys

The 4xiDraw is an open-source, home-made version of the AxiDraw ( https://www.axidraw.com/) pen-plotter machine. Originally designed to be made with laser-cut parts, later iterations of the 4xiDraw, including the version we made, were designed to be made with 3d-printed parts, with files provided. The 4xiDraw was primarily designed and programmed by one person, though some of the programs have been updated by others since their creation. The original files and program were last updated in 2015, though the creator still actively responds to the Instructables page. The 4xiDraw either requires one additional open-source program created by a different user ( https://github.com/winder/Universal-G-Code-Sender), which is still being updated, or requires an entirely different program instead of the original program and the Universal-G-Code-Sender, made by yet another user ( https://github.com/bullestock/4xidraw), which was last updated in late 2022.

Pen plotters are simple machines that use an arm that can be raised or lowered (ie, small movements on the Z-axis), to touch a pen to a page, or lift it off. While the pen is touching the page, the arm is fixed to two apertures that slide it along the X- and Y- axes, enabling the robot to convincingly draw with the pen (when correctly programmed by an associated computer) while the Z-axis motor allows the robot to control whether or not it is drawing during a certain movement.

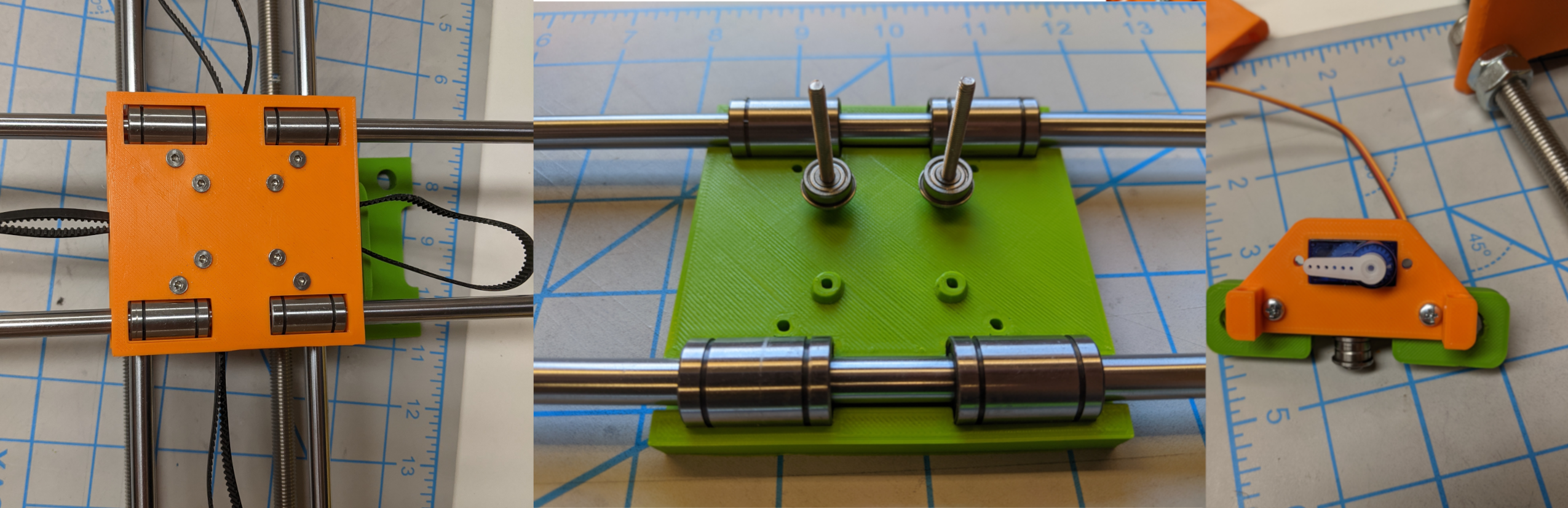

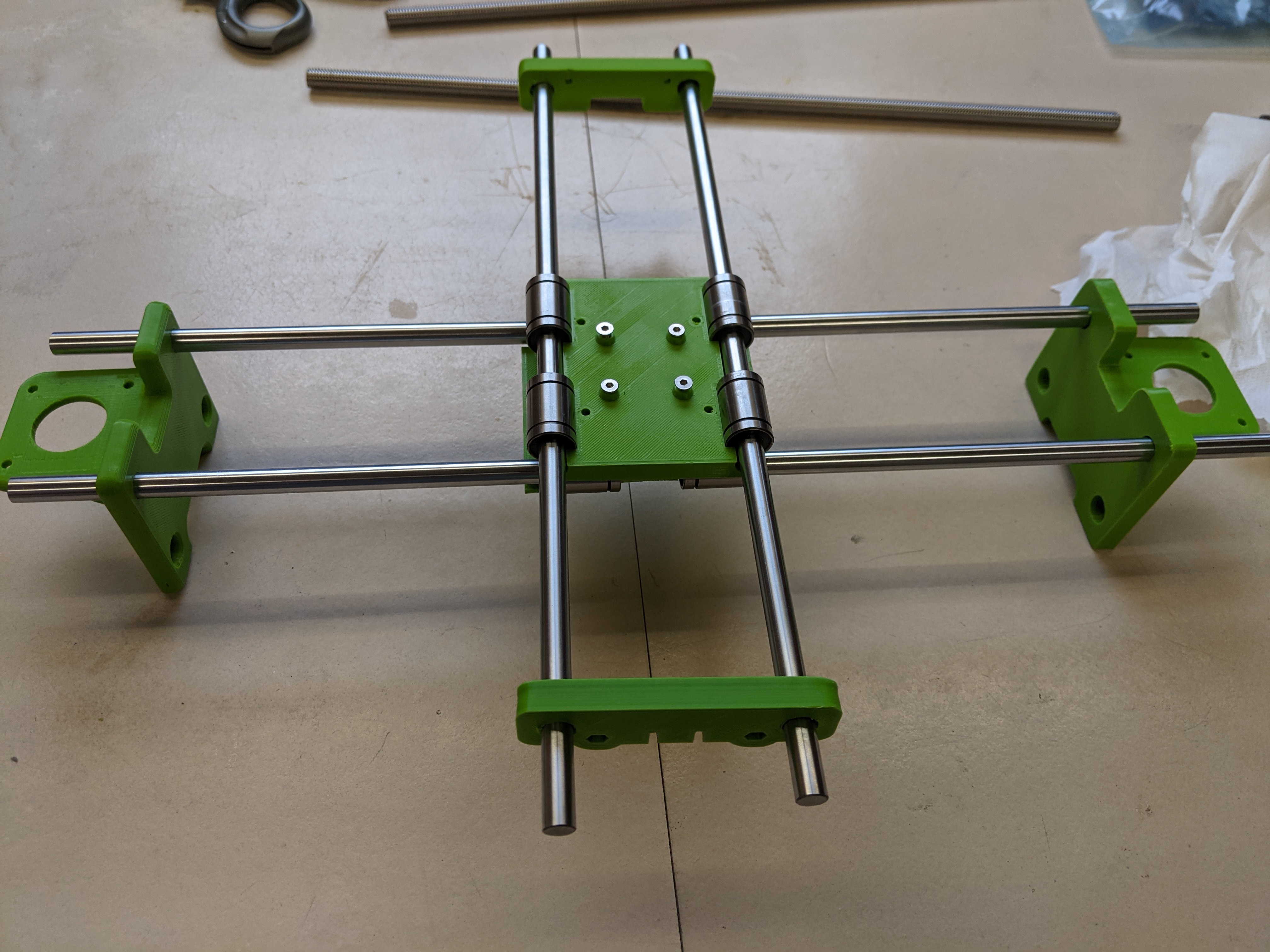

The 4xiDraw is built using several core components – alongside the 3d printed frame, the machine uses several metal rods (both smooth and threaded), stepper motors to control the arm apertures, and an Arduino UNO to control the framework.

To input instructions and make the 4xiDraw draw, the Arduino needs to be connected to a computer running Inkscape ( https://inkscape.org/), a free, open-source vector-graphics drawing program with a custom plugin. The user can then use Inkscape to export images to the 4xiDraw, which are then drawn.

For the EMM Lab, building the 4xiDraw was an experiment. The EMM Lab also acquired an iDraw pen plotter (( https://idrawpenplotter.com/), $599 CAD cost), the iDraw 2.0 A4 size, a pen plotter built on a similar frame and structure to the 4xiDraw (though there are distinct differences, namely the assembly of the motors and pen carriage). The plan for the 4xiDraw build was to compare the end result to the professionally made equivalent. While comparing the 4xiDraw with the AxiDraw directly would have perhaps yielded better experimental results (as the AxiDraw, not the iDraw, was the basis for the 4xiDraw), the AxiDraw was not available for order at the time that we began this project, and had a markedly higher cost than the iDraw. As part of the project goal was to determine if a home-made pen plotter was a viable alternative to a commercially available one, we decided that going with a well-reviewed, but more financially accessible pen plotter (the iDraw) would provide better data in the long term, as the iDraw was more likely to be purchased by others in similar situations than the AxiDraw.

While the experiment was designed, at the top level, to compare the 4xiDraw with a commercially available pen plotter, the specifics of the experiment focused on whether building an open-source pen plotter was viable, how much time it would take, and how easy it would be. Part of the goal was to build a low-cost pen plotter for use in outdoor projects, or other projects that might damage a more expensive, purchased, pen plotter.

Our hypothesis was that the 4xiDraw would be slightly inferior in quality to the iDraw (likely in output quality, rather than other fields), due to the home-made nature of the project, but that it would otherwise be a functional, and useful object.

The 4xiDraw “can easily” be done in “a weekend” [1], according to the original documentation. While the caveat “depending on your skills” is added, the instructions still suggest a shorter project. However, this “weekend” timeline doesn’t involve sourcing components, printing parts, and otherwise preparing for the project. Part sourcing took quite a long time, with Anne Pasek sourcing many of the initial parts and Kees Schuller sourcing the remaining and additional parts. Dwayne Collins at Trent University’s Odette Critical Making Studio provided assistance with, and access to, 3d printers, for producing the 3d printed components. All funding was provided by the EMM Lab. The build was done entirely by Kees Schuller, the author of this document (hence the following “I” statements).

I also found, in practice, that assembly took much longer to complete than the “weekend” window. Our assembly took place over a year (due partly to higher priority lab work taking me away from the project, but also due to ongoing issues with the materials and instructions).

The initial parts sourcing and 3d printing took about 3 weeks of intermittent time commitments – mostly waiting for shipping, and for time in the print queue (plus printing time), before assembly could begin.

The initial build began on July 7th, 2022. This initial work did not see much progress, and was set aside for the next 3.5 months, due to a combination of other projects, and limited availability. Returning to the project in November 2022, roughly 14 hours over a 12 day period saw assembly continue, stalling when new parts were needed.

Assembly remained stalled until mid-February, 2023, due to the winter holiday closure of the Odette Critical Making Studio, and then due to technical issues with the 3d printers. Work continued slowly between mid-February, 2023, and late March, 2023, at which point I realized that the 3d files needed to be designed and then reprinted, in order to fit.

Additional progress was made in late April, and the 4xiDraw carriage and armature assembly was eventually finished May 5th, 2023.

Assembling and soldering the electrical components began in late May of 2023, and continued until early June, 2023, when we realized additional parts, not listed in the instructions, were required for completion. Over the next month, attempts were made to bypass these additional components, before eventually the parts were sourced, and the electrical build was finalized in late July, and the 4xiDraw was programmed.

The 4xi was built with three primary sources of parts – 3d printed parts, which were printed in Trent’s Odette Critical Making Studio, standard hardware, tools, and components, which were sourced from local hardware stores, and specialist parts which were sourced from tech websites, such as Mouser.ca, or Spool3d.ca. For the purposes of this budget breakdown, we are dividing components into “Electrical” (for electronic components), “Physical” (for specific physical components), and “Standard” (for tools and standard lab-space equipment purchased during the process). While some parts were taxed, and others were not, we are including taxes in a final category – this is because taxes will vary based on location, and so including them in the baseline costs may not be helpful.

* The cost of the 3d printed parts was $35.07 CAD, across all the various print runs. However, this accounts only for materials, due to being printed through an academic-oriented Makerspace, and does not include power or labour costs.

Total Project Materials Cost: 572.17 CAD