Compiled for the EMM Lab by W. Kees Schuller. With thanks to Swati Mehta for web support, feedback, and experimental work

| Date | Experiment No. | Coffee filter weight | Sorbent weight | CYAN runtime | Dry sorbent (g) | CO2 captured (g) |

|---|---|---|---|---|---|---|

| 15 April | A1 | 0.88 | 10 | 13:02:00 | 10.4 | 0.6772 |

| 16 April | A2 | 0.91 | 10 | 13:05:00 | 10.16 | 0.27088 |

| 21 April | A3 | 0.85 | 10 | 13:05:00 | 10.258 | 0.436794 |

| 8 June | B1 | 0.9 | 10 | 13:10:00 | 10.37 | 0.62641 |

| 9 June | B2 | 0.87 | 10 | 13:13:00 | 10.39 | 0.66027 |

| 13 June | B3 | 1.79 | 10 | 13:09:00 | 10.28 | 0.47404 |

| 18 June | B4 | 0.85 | 10 | 13:09:00 | 10.28 | 0.47404 |

Our experiments yielded results in line with OpenAir’s average outputs for CYAN, barring the increased drying time. Across 8 tests across our two experiment periods, 10 grams of sorbent, when run in CYAN for 13 hours, captured an average of 0.559 grams of carbon, with no outlying data points. This is in line with the average output reported by OpenAir for CYAN operation. Our output within the projected range means that our build was successful, and that the existing CYAN documentation is clear enough to be useable.

However, throughout our two rounds of testing, we discovered a few things, as listed below, which complicate the simple success story told by our experimental data.

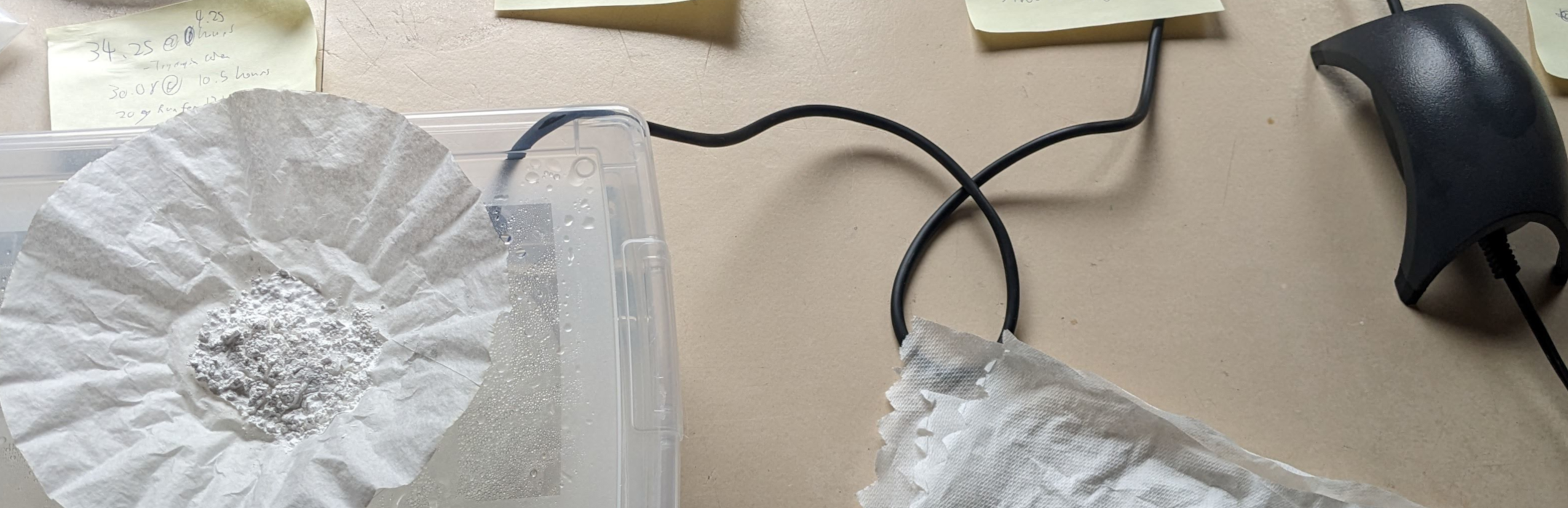

First, the calcium carbonate was not drying in the timeframe that the CYAN documentation suggested, meaning that the actual process from experiment start to useable data was about 60-108 hours per batch of hydrated lime, rather than the 18 total hours listed by Open Air. We tried to test if conditions in the lab space affected this dry time, but we weren’t able to get any kind of conclusive results. That said, one important thing to note is that the EMM Lab is not a climate-controlled lab space, being a Media Lab, rather than a wet or dry lab. Additionally, the EMM Lab does not have pristine lab conditions, or clean room conditions/policies. However, for the purposes of CYAN, this is ideal – CYAN is designed to operate in “desktop” conditions, rather than in lab conditions. This larger time and attention commitment are a problem for CYAN, making it less of the simple and easy DAC device that it is pitched as. Further, we worry that for the average user, seeing these large changes in drying time might suggest that other variables as provided by OpenAir are also unreliable, reducing faith in the project as a whole.

Second, during our experiments, we investigated the viability of alternative sorbents such as wollastonite (a sorbent that we would be able to source far more locally, and thus at reduced carbon footprint), as well as calcium hydroxide, the sorbent suggested by Open Air.

In investigating calcium hydroxide, we found that it is prepared by ‘slaking’ calcium oxide with water. Calcium oxide, then, is typically prepared by thermal decomposition of calcium carbonate. In operating CYAN, we are simply putting the carbon back into the calcium carbonate form that it was originally burnt out of. While the end result might sequester carbon, the entire process is an energy-intensive cyclical system, one where, based on the formulas Open Air provided to us, we CYAN does not achieve 100% carbonatation. Further, carbonatation is a natural process – simply exposing the calcium hydroxide to the air would eventually result in 100% carbonatation (i.e., chemical conversion to calcium carbonate).

We reached out to OpenAir about this issue through their Discord server (their main forum for discussion). Based on our conversation, OpenAir is fully aware of the issues with using calcium hydroxide as a sorbent. However, for OpenAir, using calcium hydroxide as an imperfect sorbent is necessary in order to develop a functional CYAN build in anticipation of the discovery or invention of a carbon neutral sorbent. Again, per the conversation, OpenAir sees it as more important to build a working CYAN model than to look for more carbon neutral sorbents that also have the accessibility and output that they are looking for.

While the experimental results and science behind CYAN turned out to be disappointing, the build itself was a success. Functioning exactly as expected, and with data results in line with what OpenAir had already recorded, CYAN proved to be a successful experiment, both in terms of anticipated output, and in terms of building an open source object for the lab.

Looking to our processes throughout the CYAN build and experiments, we can see a few areas for improvement, but also a few areas where we have improved since the 4xiDraw build. CYAN was built in around one hour of work shared between three members of the EMM Lab. This was more effort than was needed – CYAN could have been built by just one member in the same amount of time (or a shorter length). However, this inefficiency was necessary, as collaboration, and a shared affective experience of building and turning on CYAN was important to the overlapping goals of the project. During the build, following the CYAN documentation provided by OpenAir, including one of multiple build demo videos, made for a relatively easy assembly, with little room for error. This partly accounted for a smoother assembly than with the 4xiDraw, though part of that increased smoothness can be attributed to the lessons learned during the 4xiDraw build process about reviewing and understanding instructions, and having the relevant tools on hand.

Moving to a reflection on the experimental data, while the CYAN build and experiments were both technically successful, aligning with the expected output based on OpenAir’s documentation, and proving to be a simple and accessible build, the larger project proved unsatisfactory and unsuccessful for a few reasons.

First, part of our reason for building CYAN was to adapt it for use with sorbents and chemicals other than calcium hydroxide, specifically wollastonite. As mentioned, wollastonite is available locally to the lab, at a quarry focused on ecological preservation and carbon sequestration in its quarrying (Canadian Wollastonite - https://www.canadianwollastonite.com/). More importantly for the purposes of CYAN, wollastonite production does not release carbon, unlike calcium hydroxide production. Unfortunately, however, further research into wollastonite made it clear that it wouldn’t work with CYAN – both in terms of timescale, and in terms of physical construction. Specifically, when working with wollastonite, we would have needed to measure silicon output in aerial release, precipitate, and in-solution volumes, in order to then calculate how much carbon had been captured. Wollastonite reactions also take a longer timeframe than calcium hydroxide. These presented obstacles n terms of timescale, materials, and expertise, and as such, this further use of CYAN was deemed not viable.

Second, even though our CYAN numbers were equivalent to OpenAir’s projections, those numbers are very low – we only captured around half a gram of carbon captured per batch of sorbent. While we were initially happy with these numbers when beginning the experiment, after seeing the work required, the cost, the energy use, and the fact that calcium hydroxide production releases more carbon than we were sequestering, we were disappointed with this result. While this disappointment tied into some of the affective concerns of the project, it was still not what we were hoping for in our outputs.

Part of the problem with these results and outcomes being unsatisfactory for the lab is that all of this information was available from the start. If we had spent more time investigating wollastonite before building CYAN, we would have known that we wouldn’t be able to use it as a sorbent in CYAN (or, at least not in a way that produced experimental data). While we investigated the function and output of CYAN, and compared it to experimental run-times, and thus were prepared for the low output based on input, we weren’t prepared for that in context. And, if we had looked at the chemistry of the reaction, we would have known that CYAN doesn’t actually do climate work (or, at least not on the Carbon Capture axis). Again, this re-emphasizes some of the lessons we learned with the 4xiDraw – the need to do research before beginning an open source hardware project. Spending a bit more time understanding the project, in all its dimensions, is going to be helpful. And, of course, open source projects and technology in general, are imperfect – they are works in progress, almost by definition. Taking on DIY open source projects means acknowledging that, and preparing for the possibility of failure, even if you do everything right.

That said, our work with CYAN has still proven useful – it’s led to numerous fruitful conversations about open source, about communities of practice, and about climate imaginaries versus climate action. Its role of providing a window into the affects of DIY climate activism has been vastly successful, both by assessing our own reactions to the project, and by allowing us to better understand OpenAir. And, it helped us understand both that last point from the above paragraph – that sometimes, failure happens anyways – and, helped us understand something which is perhaps more normalized in the sciences – that a failed experiment can yield just as much information and value as a successful one.